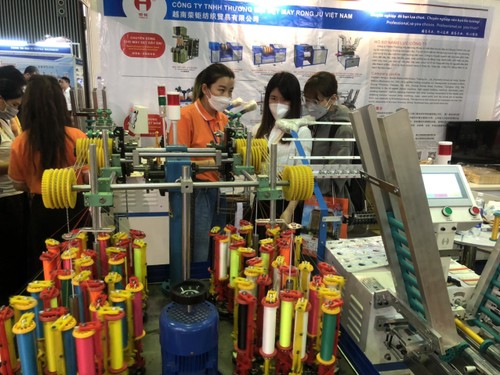

New automatic machines and equipment of the garment and textile industry will help its businesses reduce workforce. (Photo: Le Hang/VOV’s reporter in HCMC) New automatic machines and equipment of the garment and textile industry will help its businesses reduce workforce. (Photo: Le Hang/VOV’s reporter in HCMC)

|

The Hoa Binh Garment Company used to have 1,500 employees. Every year during Tet and other holidays, the company’s leaders had to deal with labor fluctuations. This headache is being alleviated by digital transformation.

In 3 years the business has reduced its employees and production costs 40% while increasing productivity 15%. The money freed up by decreasing the number of workers has been used to increase the wages of the remaining workers. Management department employees can work at the company 2 days a week and the rest of the week control the work from home computers using the company's new management software.

Nguyen Chi Phuong, Chairman of the Hoa Binh Garment Company, said his business has begun a digital transformation of everything from production to management.

He said all production machinery and equipment for sewing and packaging are imported, and most of the production lines have been automated and connected to the server, so managers can monitor each stage of each line.

Phuong explained in details, “There are 2 computers in the production line, one managed by the line leader to monitor productivity. The other is at the end of the line to do quality checking. Since every detail is coded with a number, quality checkers find it easy to determine where mistakes occurred. The person who enters the number for the products only knows the number, not who performs the work, so it is impossible to play favorites.”

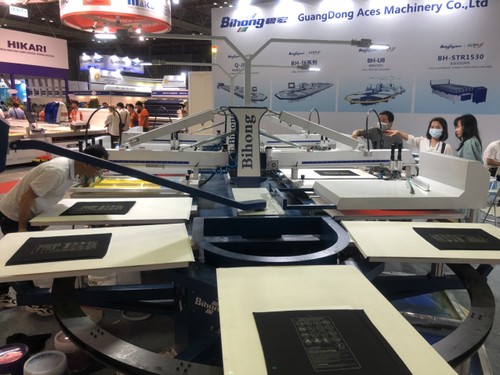

New equipment with outstanding features help garment and textile businesses digitalize each step. (Photo: Le Hang/VOV’s reporter in HCMC) New equipment with outstanding features help garment and textile businesses digitalize each step. (Photo: Le Hang/VOV’s reporter in HCMC)

|

Many garment and textile companies began digital transformation even before the COVID-19 pandemic.

Pham Xuan Trinh, CEO of the Vietnam National Textile and Garment Group, said Vinatex, is in the second phase of digital transformation. The business uses a digital platform to control production, sales, supply, inventory, prices, inputs, and outputs.

“We’ve built a digital conversion system that shares software. The group uses this software to manage all parts of the system. We can control online the productivity, labor, inventory, and market value of the entire market, enabling member businesses to quickly handle their operation,” said Trinh.

According to a survey by the Vietnam Textile and Apparel Association, more than 80% of garment and textile enterprises hope digital transformation will increase efficiency and reduce costs.

But not all businesses have the resources to do this. Small businesses, especially, lack the capital and personnel.

The Thai Thanh Linen Company has more than 100 employees. After the pandemic, only half of the workers returned to work. The business is still using its old labor-intensive ethods, and its productivity is not high.

Luu Manh Hung, the company’s Deputy Director, says the company really wants to pursue digital transformation, but lacks capital and human resources, adding it has only digitized a few things so far

According to Hung, “Small and medium-sized enterprises like my company need government policies to improve governance capacity, introduce technologies for each specialty, and make it easier for us to access capital. Once we have those three things, our digital transformation can be successful.”

The company has asked management solution suppliers for help in training and developing suitable software.

According to Nguyen Thi Tuyet Mai, Chief Representative of Vitas in Ho Chi Minh City, “We’ve cooperated with the Vietnam Finance Leasing Association. If there are green investment or digital transformation projects that are feasible, we’ll work with banks to approve the projects. The Association will buy the hardware needed for digital transformation. The businesses will lease the hardware until it’s fully depreciated.”

Digital transformation is vital for garment and textile enterprises because cheap labor is no longer a competitive advantage.

They face fierce competition in the export market in terms of cost and labor productivity. What they need is support mechanisms and policies to expedite digital transformation.